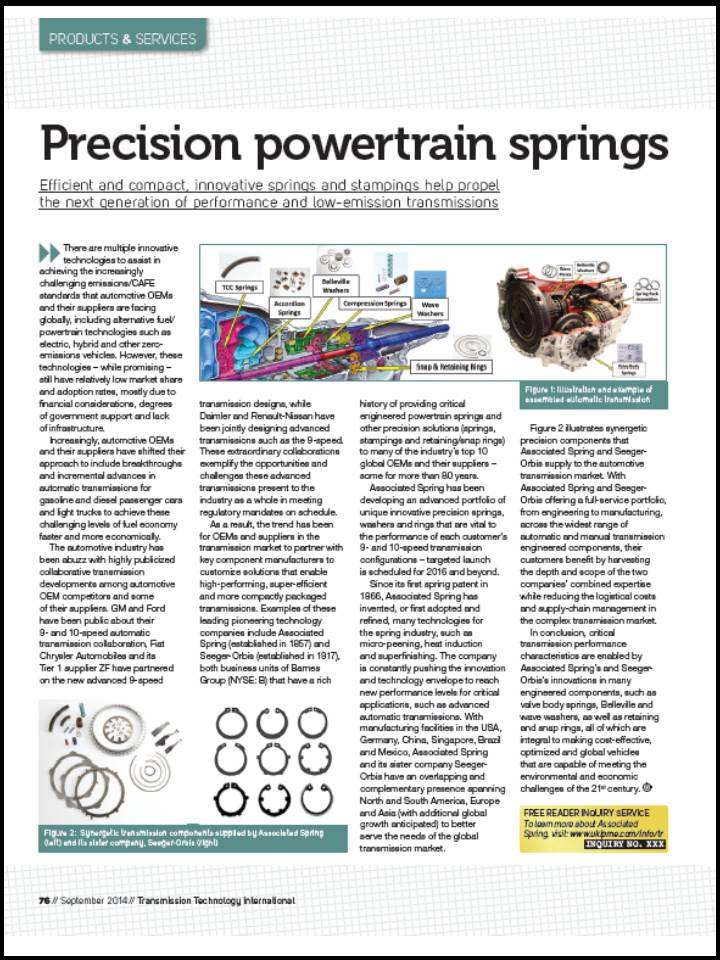

Barnes Engineered Components showcase our diverse and synergetic offering through the new Innovation Wheelhouse advert in Transmission Technology International Magazine. To learn more about our engineered system solutions visit Barnes EC and our four leading businesses; Associated Spring, Seeger-Orbis, Hänggi and Associated Spring Raymond. To view the magazine and advert please click here.

Barnes Engineered Components have again published an article in Transmission Technology International magazine. The editorial piece discusses the continued regulations on emissions and how innovations from Hänggi in GDI development are helping OEMs advance fuel economy. Working with our customers’ to solve application issues is the foundation of Barnes Group’s storied 160 year history and we pride ourselves on finding innovative solutions. Read the article here and for more information on Hänggi or to request a quote, please visit their website.

Discover our exciting New Associated Spring, Seeger, Hanggi Automotive Innovation Wheelhouse in the Automotive News- Dec 2017 Issue

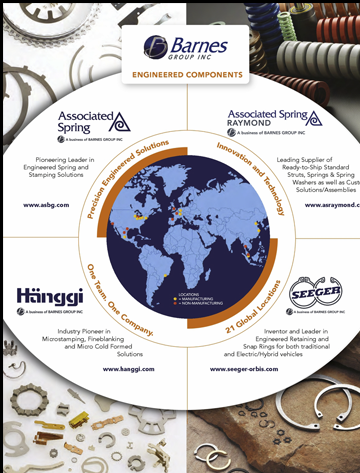

ENGINEERED COMPONENTS

Barnes Engineered Components (EC) with its renowned brands (Associated Spring, Hänggi, Seeger Orbis, and Associated Spring Raymond) is the leading global supplier of precision custom engineered and ready-to-ship solutions.

With our engineering capability & manufacturing expertise, we solve complex (product, process) design challenges & help you achieve increased performance & optimal lifecycle costs. Our springs are critical in applications across multiple industries from Transportation to Aerospace, Construction, Medical, Energy, Telecommunications, Industrial, Consumer Goods & others.

Engineered Components has a breadth and depth of expertise spanning from aerospace/defense to transportation transmission springs; retaining and snap rings to precision micro-stamped/fine-blanked solutions for GDi/fuel injection; as well as medical and high-tech/digital micro manufacturing to other innovative high performance advanced precision components, engineered struts and assemblies. As a world-class manufacturer and supplier to the high-tech/telecom, transportation, medical, construction/mining, marine/recreational, energy, and other industrial markets, the EC organization spans multiple global strategic locations across North/South America, Europe, and Asia.

Barnes Engineered Components have again published an article in Transmission Technology International magazine. The editorial piece covers the continued innovations from Associated Spring in Arcuate spring development, while showcasing the continuous improvement in our spring development programs. Working with our customers’ to solve application issues is the foundation of our storied 160 year history and we pride ourselves on finding innovative solutions. Read the article here and for more information or to request a quote, please click here.

To compliment our Article in Transmission Technology International magazine, We have also placed an advert in the same publication to promote our brand synergies across Engineered Components' four leading businesses; Associated Spring, Seeger-Orbis, Hanggi and Associated Spring Raymond. To view the magazine and advert please click here.

In support of our continued #1 position for Precision Engineered Custom and Catalog solutions, Barnes Engineered Components have advertised in the August edition of D2P Magazine. We continue to exhibit at the D2P shows and will always be happy to discuss your Catalog & Custom application solutions. To make and enquiry or for more information please click here to contact us.

May 2017 Barnes Engineered Components is proud to celebrate two landmark anniversaries for its world leading brands; Barnes Group and Seeger-Orbis. Barnes Group Inc is celebrating 160th anniversary and Seeger-Orbis is celebrating their 100th anniversary. To mark the occasion our team at CTI Novi had a dual ceremonial cake cutting celebration with our customers and visitors. Pictured left; Scott Mayo; SVP & President, Barnes Industrial. Barnes Engineered Components 4 brands & team are proud of our DNA of 160 yr. of innovations & commitment to be a valued partner, leading with engineered differentiated innovative solutions to provide our customers with a global competitive edge.

The EC organization spans 21 global manufacturing and nonmanufacturing strategic locations, with over 1,500 employees dedicated to collaborating with customers, adding value through innovation and state-of-the-art

technologies and strategies such as BES Next Generation, and consisting of four leading brands: Associated Spring, a leader in engineered spring and stamping solutions; Associated Spring Raymond, a leading supplier of ready-to-ship standard struts, springs and spring washers as well as custom solutions/assemblies; Heinz Hanggi, a leader in microstamping, fineblanking and micro-cold-formed solutions including state-of-the-art GDI solutions that are superior to laser drilling/EDM wire alternatives;and Seeger-Orbis, a leader in engineered retaining and snap rings for traditional as well as electric/hybrid vehicles.

December 18, 2014 - Plymouth, MI

Associated Spring (AS), a business of Barnes Group Inc. (NYSE:B), and an industry leader and pioneer in engineered precision spring and stamping solutions, is pleased to announce the opening of its new Innovation and Technology Center (AS ITC) in Plymouth, MI. With this new facility, Associated Spring solidifies its commitment to innovation and market leadership in engineered precision spring solutions for its customers worldwide.

Winter 2014 – Associated Spring has built up an impressive and loyal customer base, but its growth into new key markets is a testament to the company’s continuing dedication to technology and innovation. The company’s cornerstone in the automotive and industrial sectors is being stretched into aerospace, defense, and green energy because of key technologies the company has pioneered and continues to improve upon.

Fall 2013 - Associated Spring, a business of Barnes Group Inc., is an organization that drips with the history of the spring industry. It is one of only a few companies in the U.S. that have been in the business of making springs for more than 150 years.

Summer 2013 - The design goal of any spring is to absorb and return energy repeatedly without failure. Through years of experience, testing and data collection, it is fairly easy to estimate how many cycles a spring will survive before fracture for a given material grade and processing (i.e. stress relieving, shot peening, pre-setting, etc.).